APPLICATION OF DRIVE EQUIPMENT

Modern production is impossible without drive technology. Depending on the drive, it can be divided into: pneumatic, hydraulic and electric.

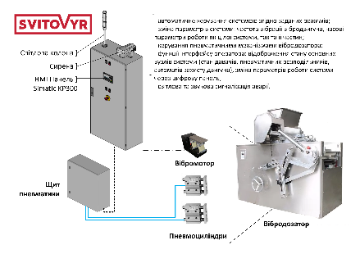

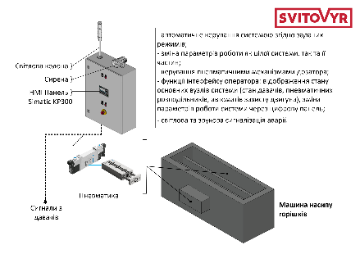

Pneumatic actuator. Its advantages are speed and high reliability. In our projects we use Festo pneumatic devices. Which allows to guarantee the Customer, high reliability and productivity.

- we work with all types of cylinders: rod, rodless, rotary;

- install protections against condensation of working gas;

- select and install compressors;

- modernize and restore the operation of existing systems;

- we develop control systems and monitoring of pneumatic devices.

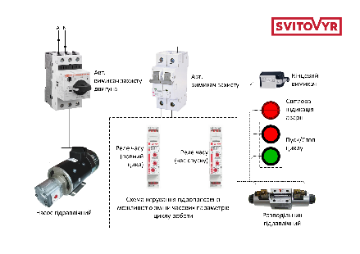

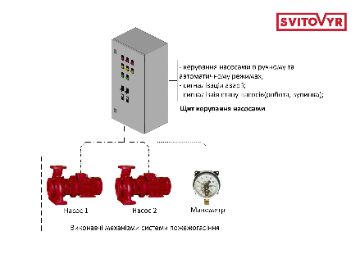

Hydraulic drive. Hydraulic units are installed in places of the system where a large load is required. When working with a hydraulic drive, it is necessary to have an oil station.

Our company deals with:

- design and installation of hydraulic systems;

- production of non-standard hydraulic cylinders;

- selection, monitoring and management of oil stations.

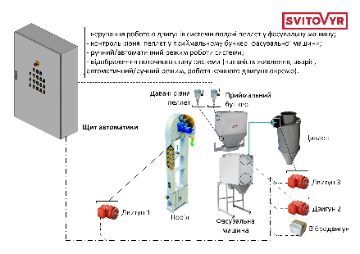

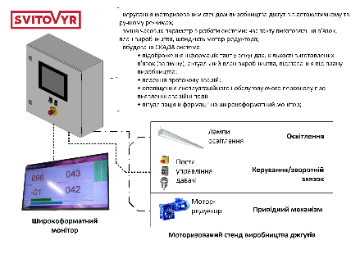

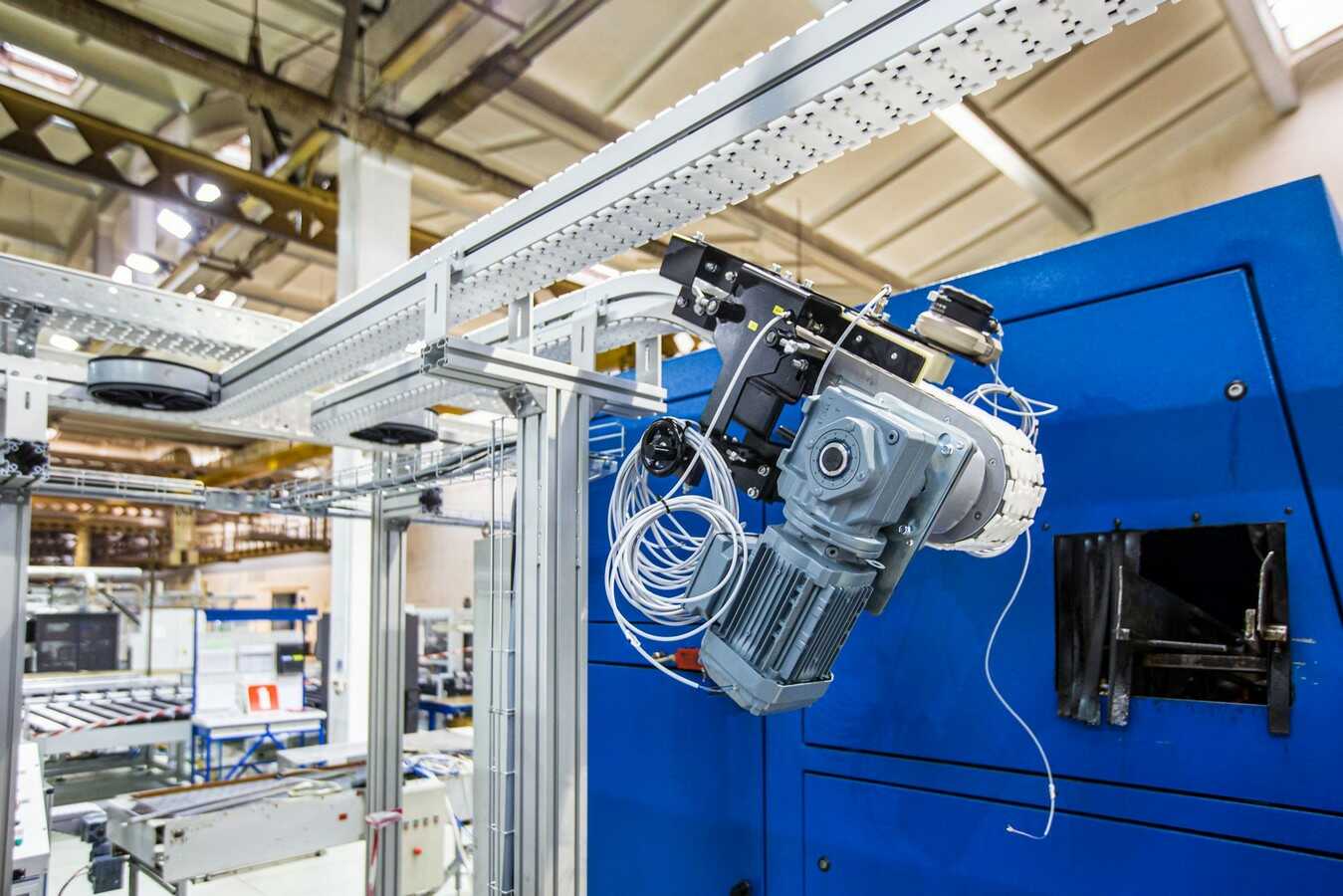

Electric drive. For the engine to work properly as part of the system, it must be properly selected, mounted and connected. Particular attention should be paid to the logic of engine management, and the selection of the correct protections, which will not only increase the shelf life of an individual engine, but also be able to "predict" the time of replacement or service. Which in turn makes it possible to plan the technological process and the opportunity to prepare for the shutdown of the production line or mechanism.

In our projects we use the following electric motors:

- synchronous;

- asynchronous;

- step;

- servo.

To adjust the algorithms of motors (depending on the type of motor), we use frequency converters, soft starts and motor controllers from different manufacturers: Siemens, Schneider Electric, Festo, Danfos, Mitsubishi and many others.

- we have extensive experience in designing automated systems using drive technology;

- we develop new systems, and also we adjust systems which are already put into operation;

- we provide service support for maintenance and monitoring.

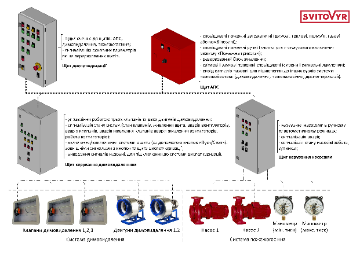

drive systems

Implemented projects

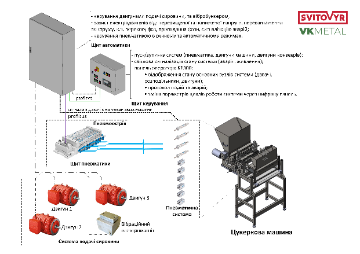

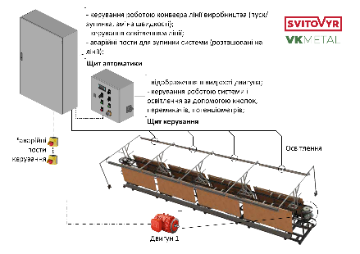

Candy machine

#foodindustry # mechanicalengineering #automation #drivesystems #PLC #HMI #SCADA #automationcabinets #cabinets #cabinetsproduction #mechatronics #pneumatics #pneumaticsystems

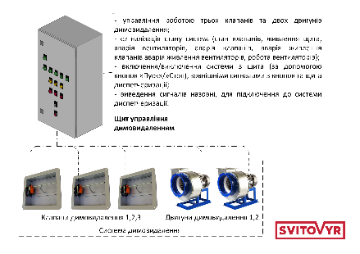

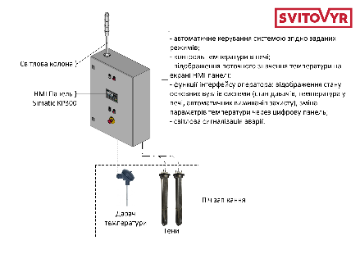

Smoke extraction system

#lifesafety

#construction #automation #cabinets #drivesystems #automationcabinets #cabinets #cabinetsproduction

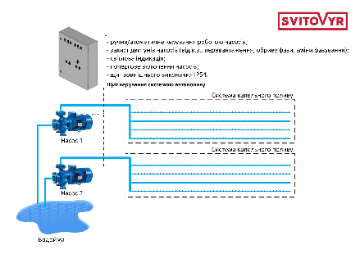

Irrigation system

#agriculture #agriculturalcomplex #automation #drivesystems #automationcabinets #cabinets #cabinetsproduction

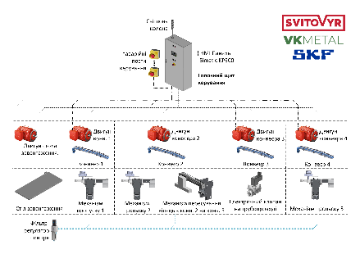

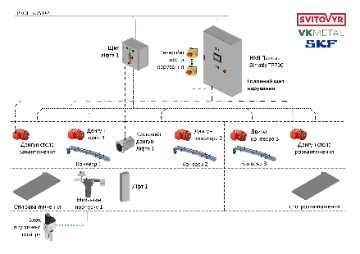

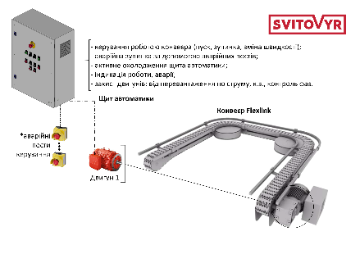

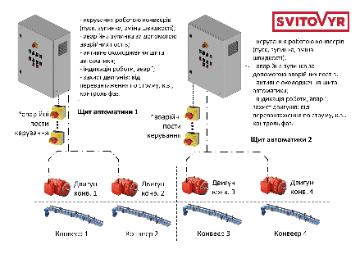

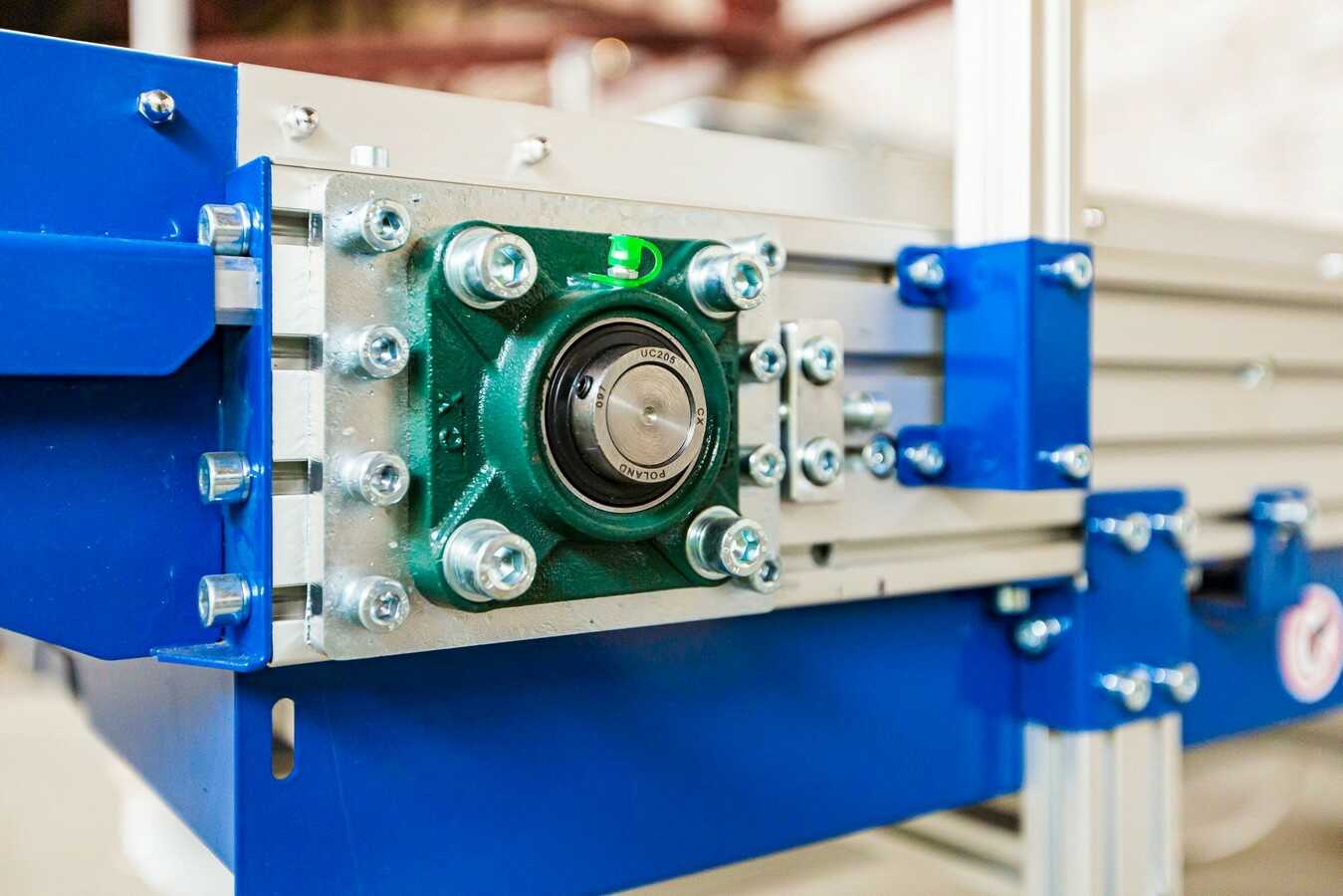

Coveyer bearing line

#metallurgy #automation #drivesystems #PLC #HMI #SCADA #cabinets #cabinetsproduction #automationcabinets #mechatronics #pneumatics #conveyor

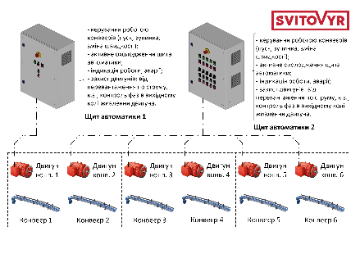

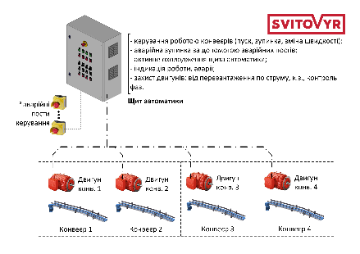

4 conveyor lines

#metallurgy #automation #drivesystems #PLC #HMI #SCADA #cabinets #cabinetsproduction #automationcabinets #mechatronics #pneumatics #conveyors

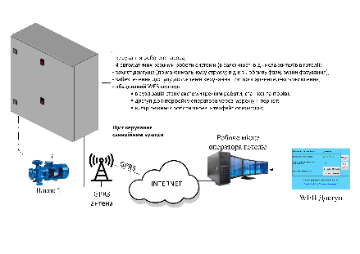

Rehabilitation. ARDUINO

#cleaningfacilities #buildingindustry #automation #industrialautomation #drivesystems #PLC #SCADA #cabinets #automationcabinets #cabinetsproduction

Rehabilitation of Dolyna

#cleaningfacilities #buildingindustry #automation #industrialautomation #drivesystems #PLC #SCADA #cabinets #cabinetsproduction #automationcabinets

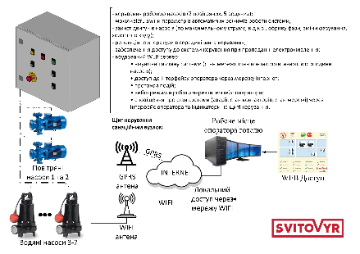

Sanitation of Skhidnytsia

#cleaningfacilities #buildingindustry #automation #driveequipment #PLC #SCADA #cabinetsproduction

Cable and wire production line

Engine protection

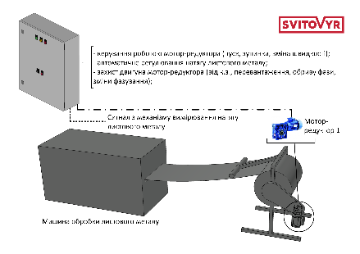

Roll machine

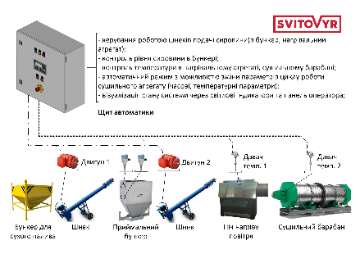

Drying system

Paving palletizing system

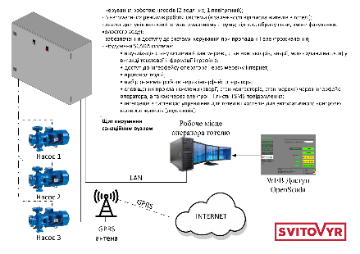

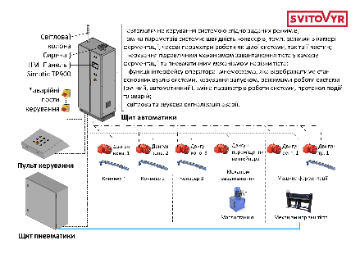

Dispatching and smoke removal

Vibrating hopper

Nut embankment management

LOADING IN THE PACKING MECHANISM

Incubator

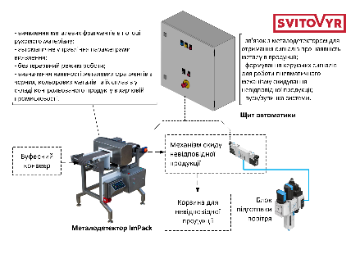

Metal detector

Washing mashine

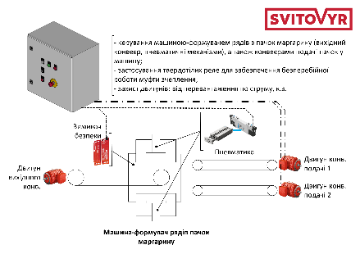

Margarine packer

Refrigeration unit

Hydraulic press control panel

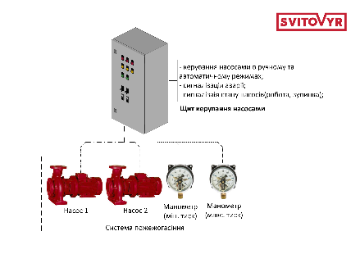

Fire pump control panel

Roundabout

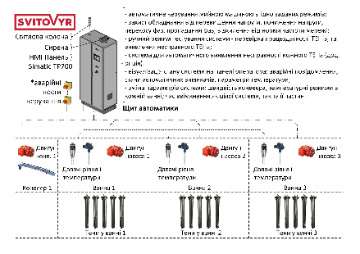

Conveyor system 1

Conveyor system 2

Conveyor system 3

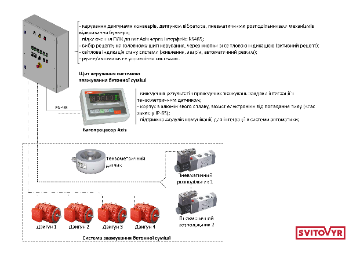

Concrete mix weighing line

Slicing the dough

Baking oven

Feedback

If you are interested in our activities, you want to cooperate, or have specific questions - leave a request by filling out the form in the left column and we will be sure to contact you.

Сategories

© 2020 All rights reserved.