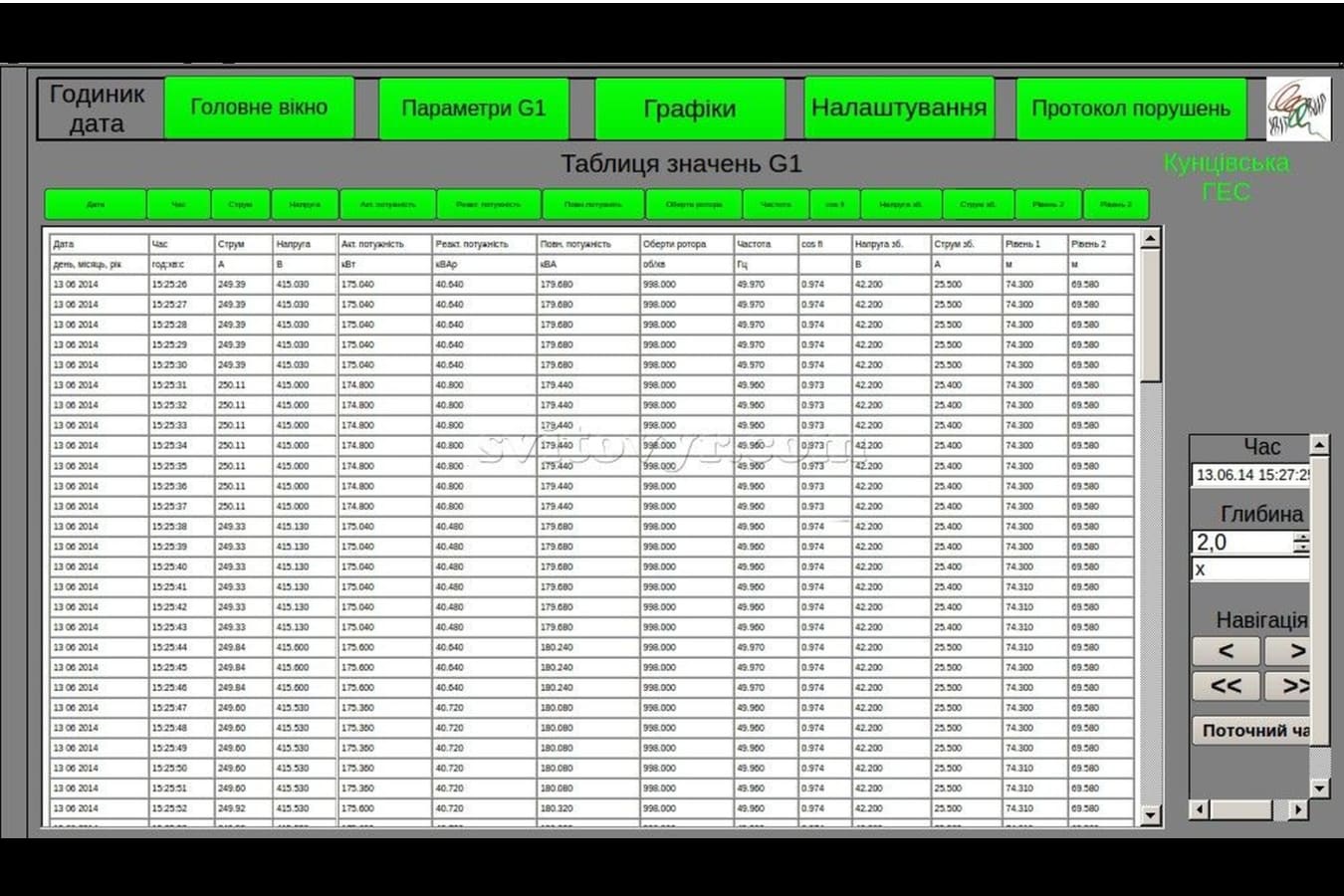

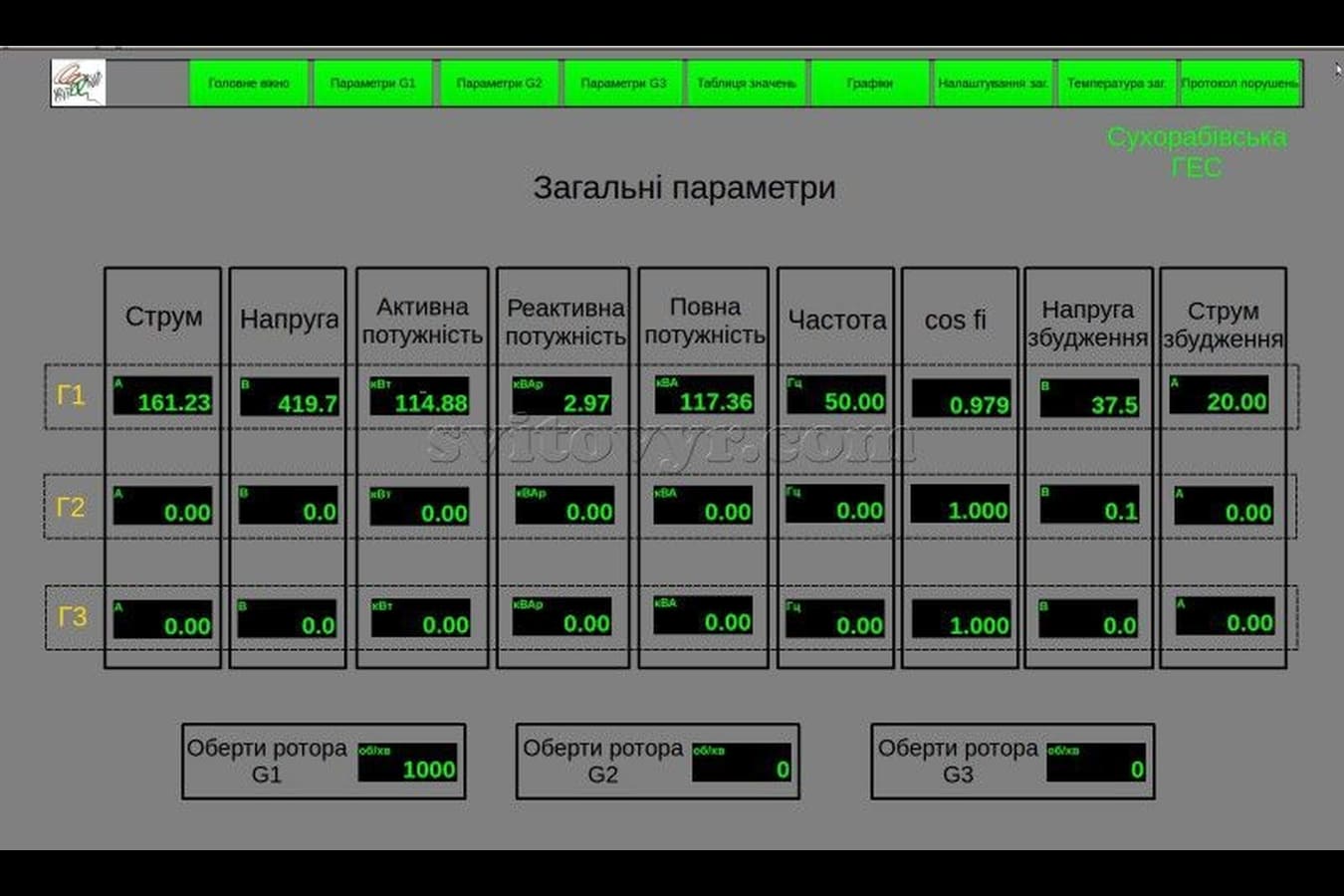

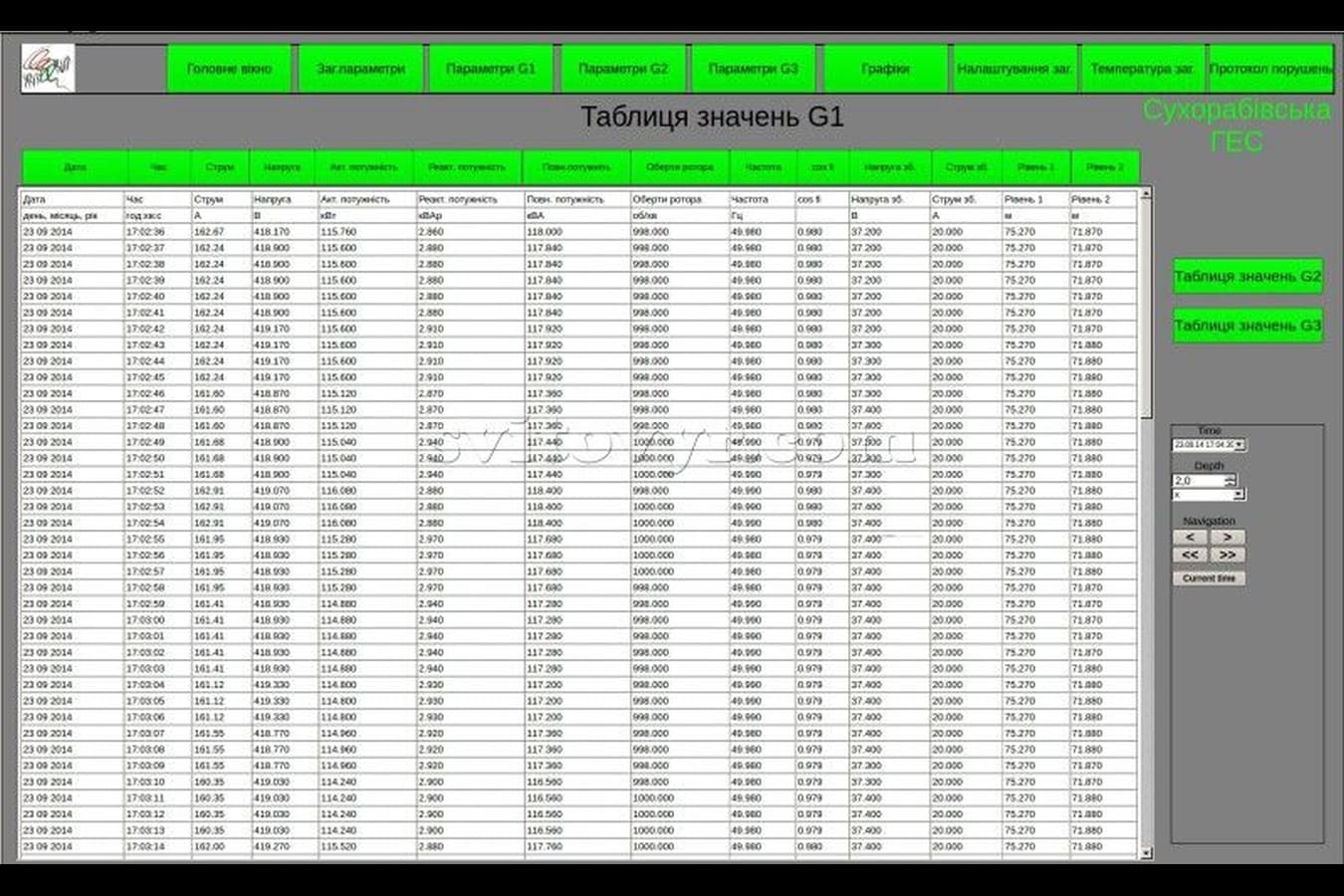

PLC receives:

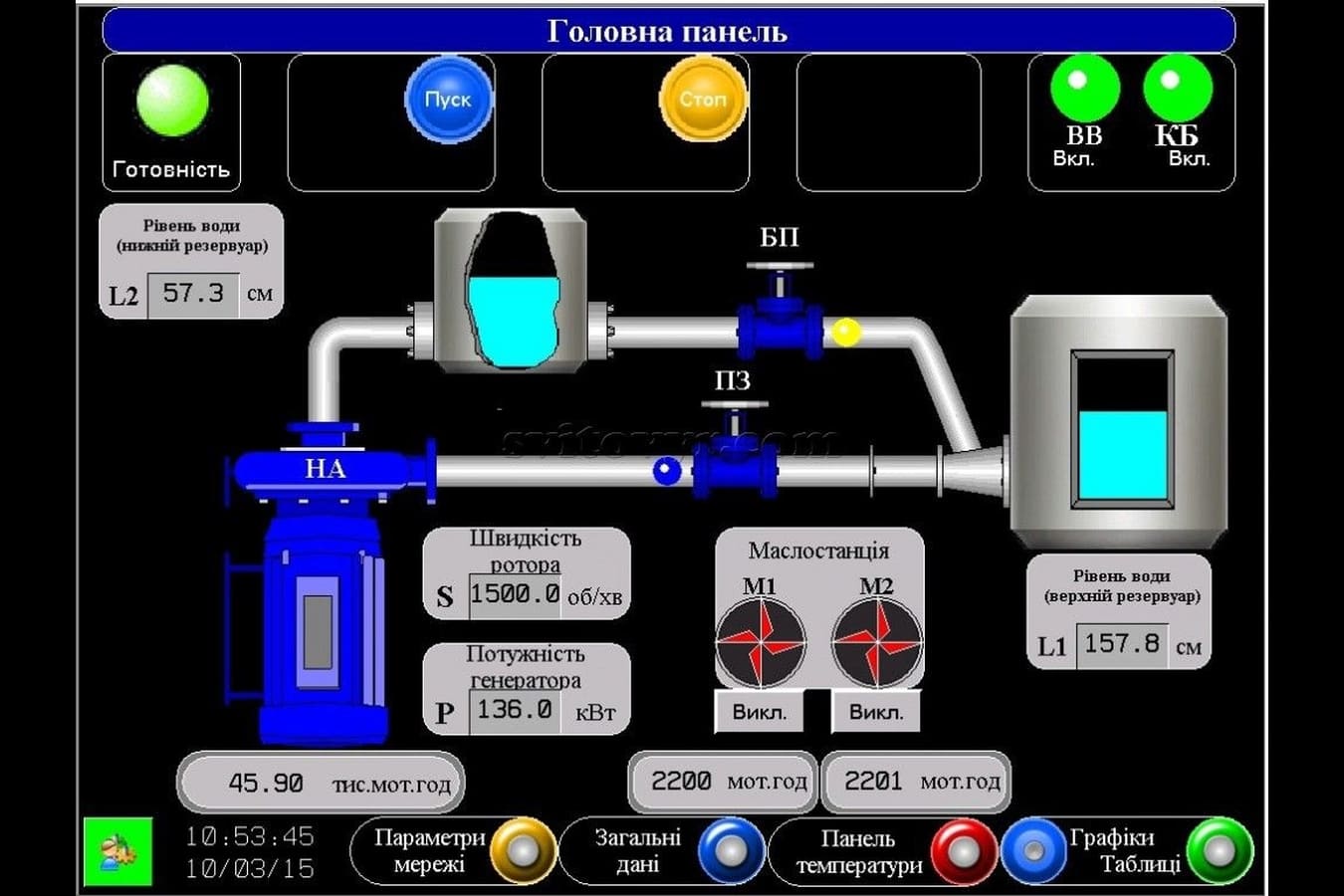

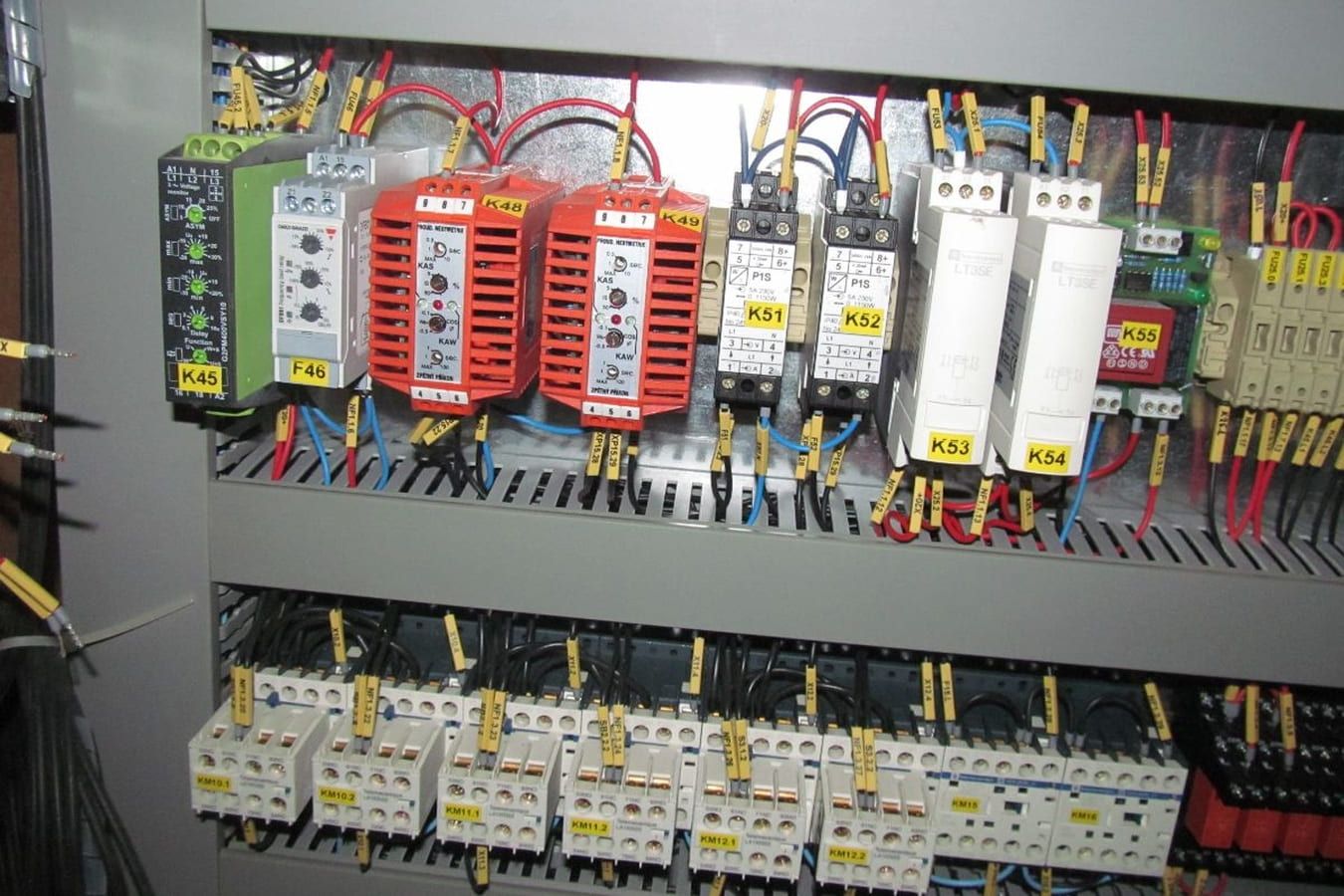

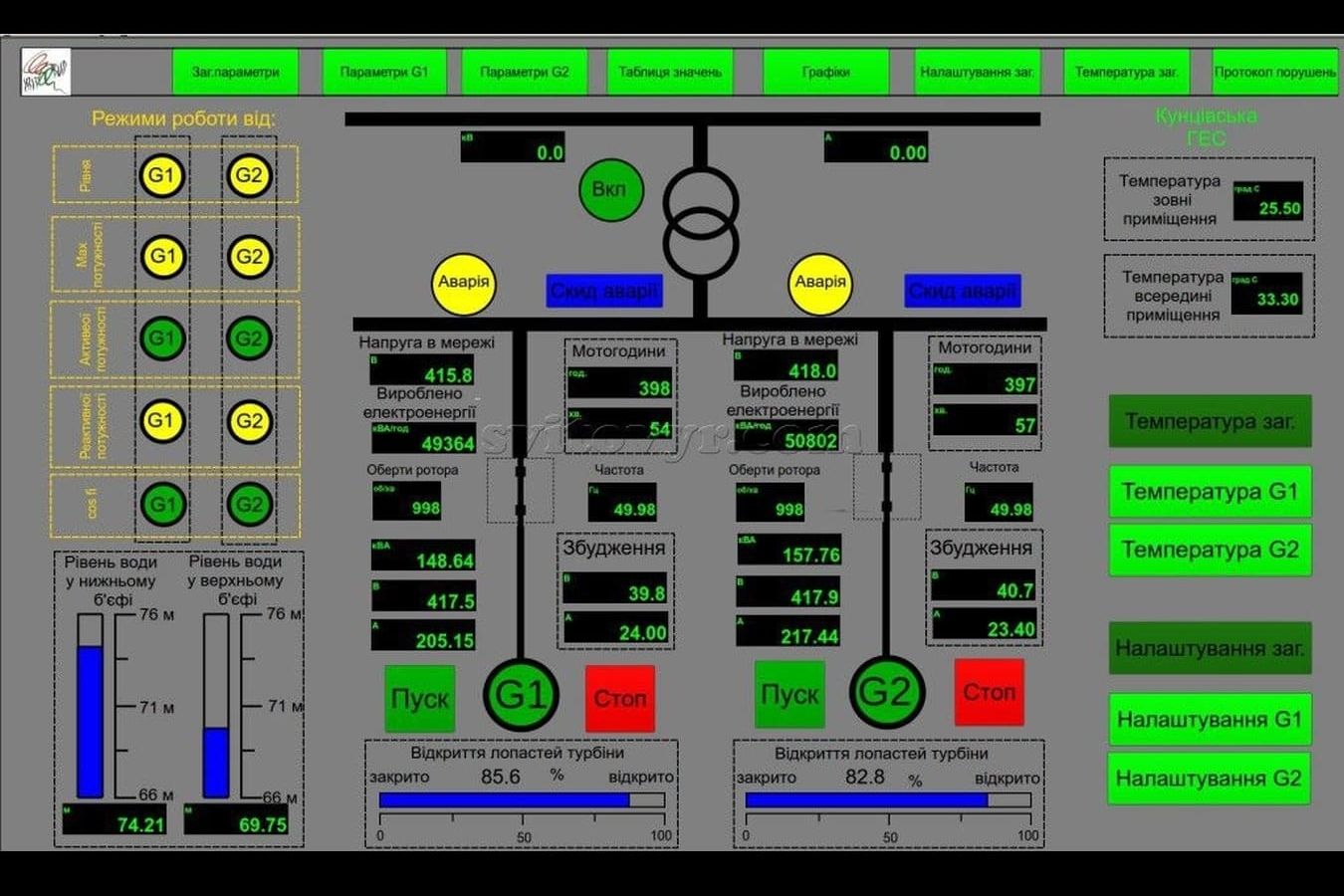

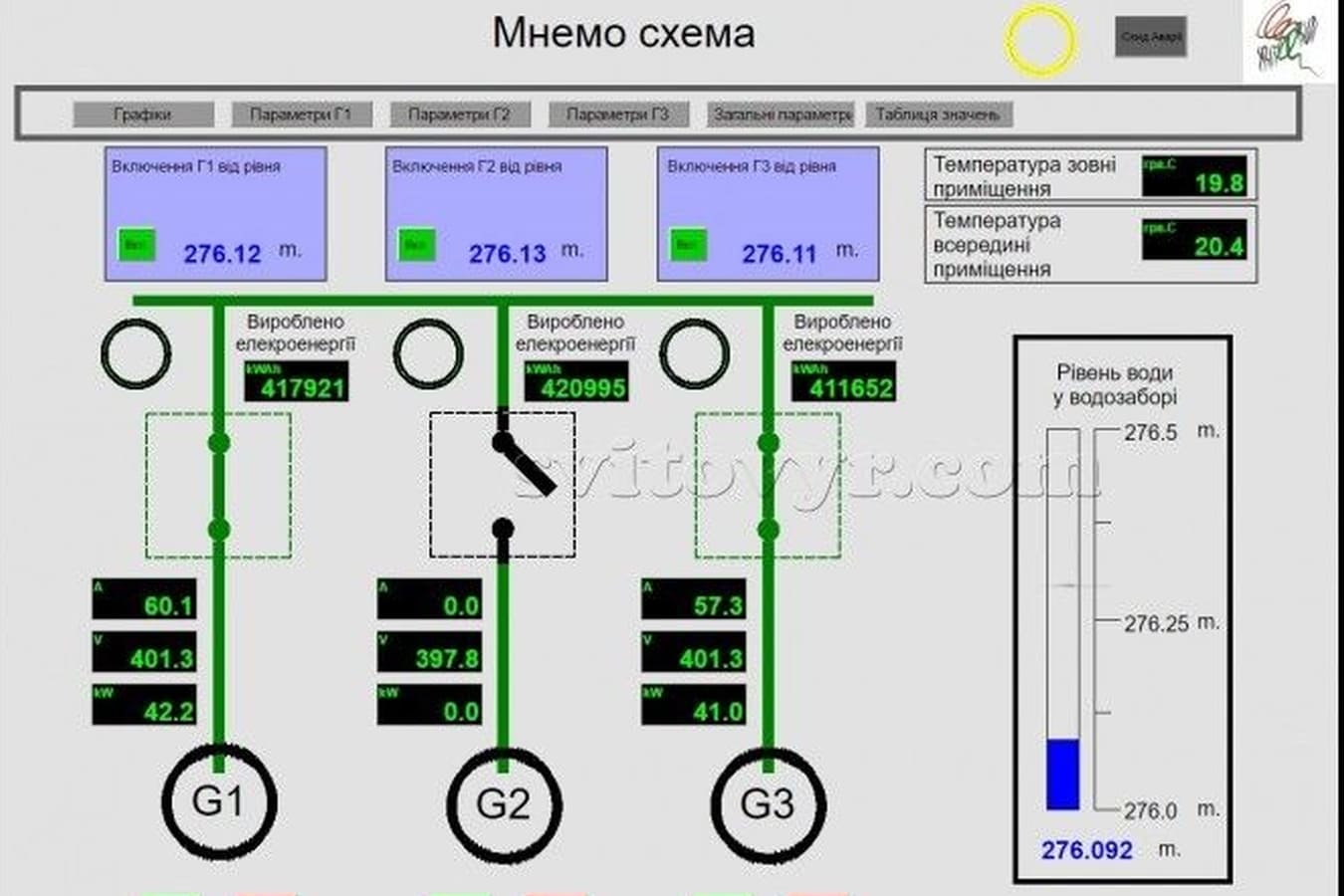

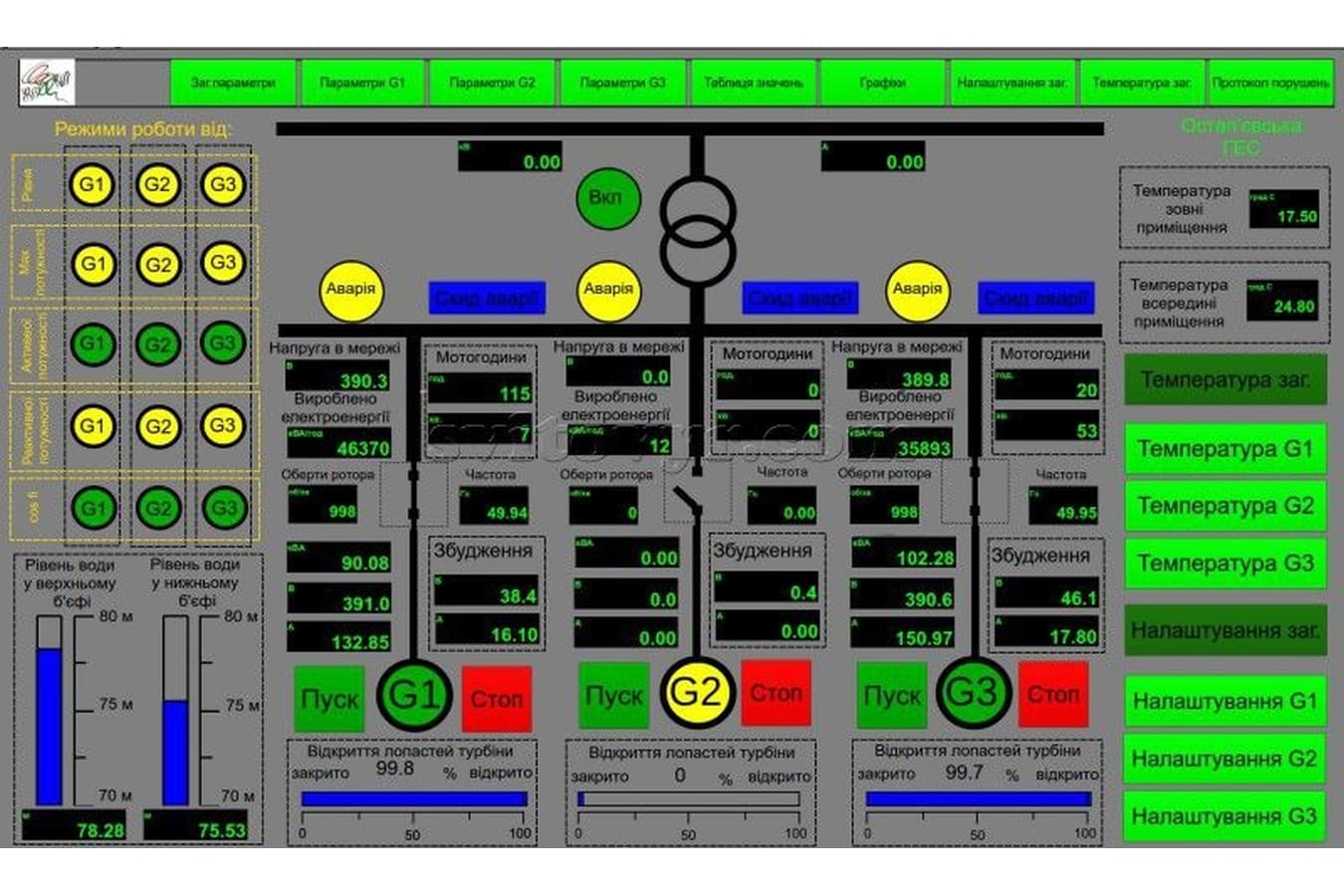

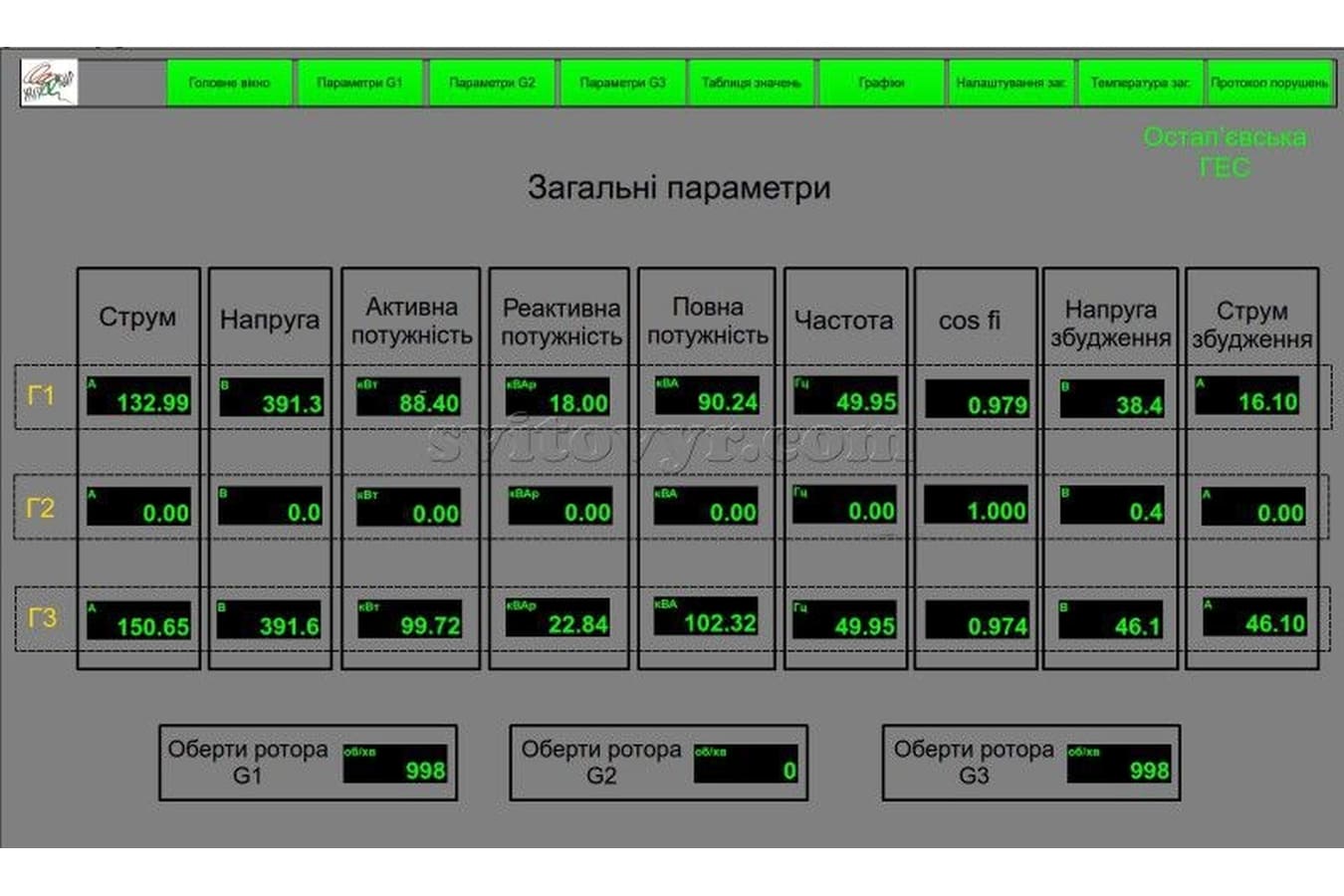

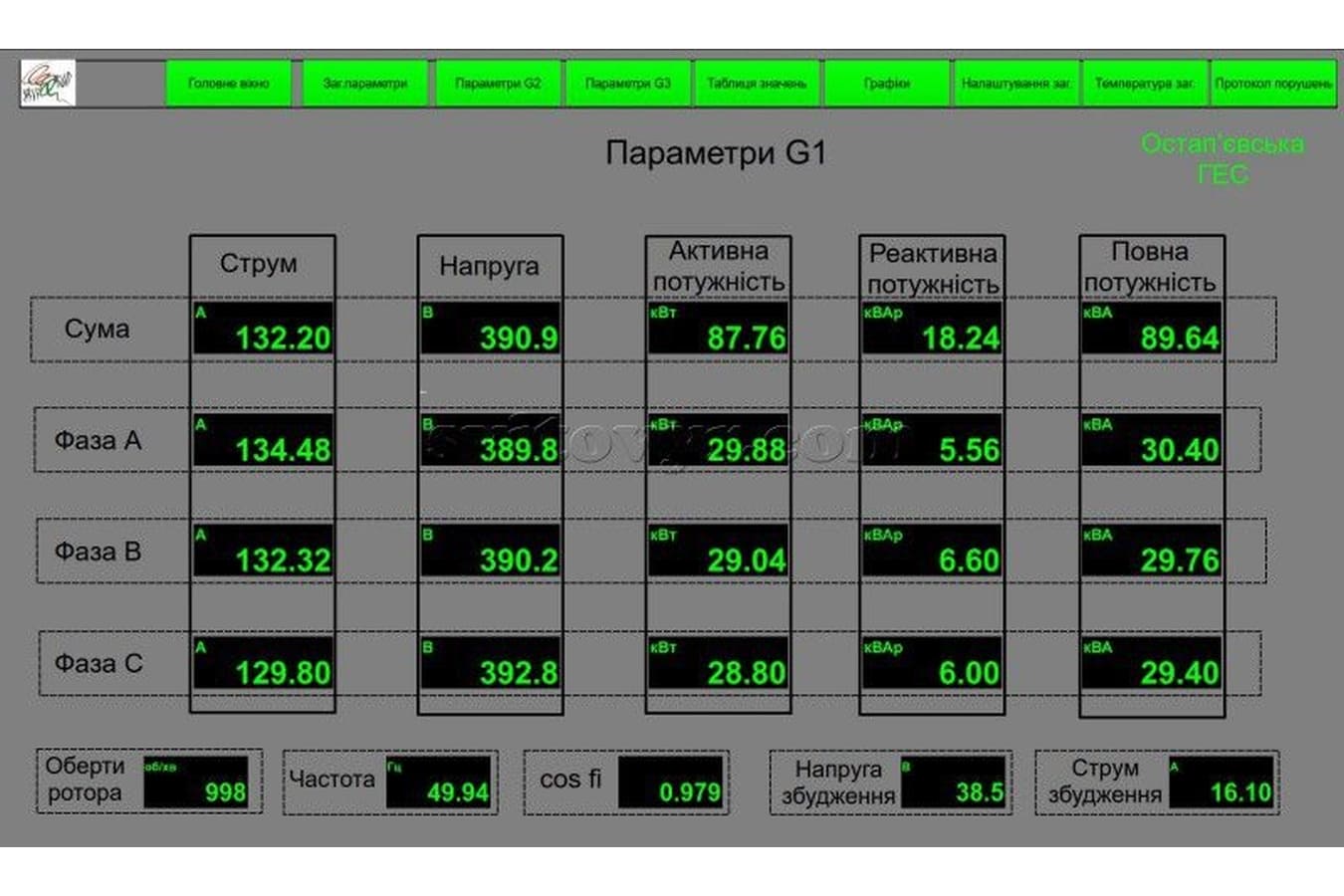

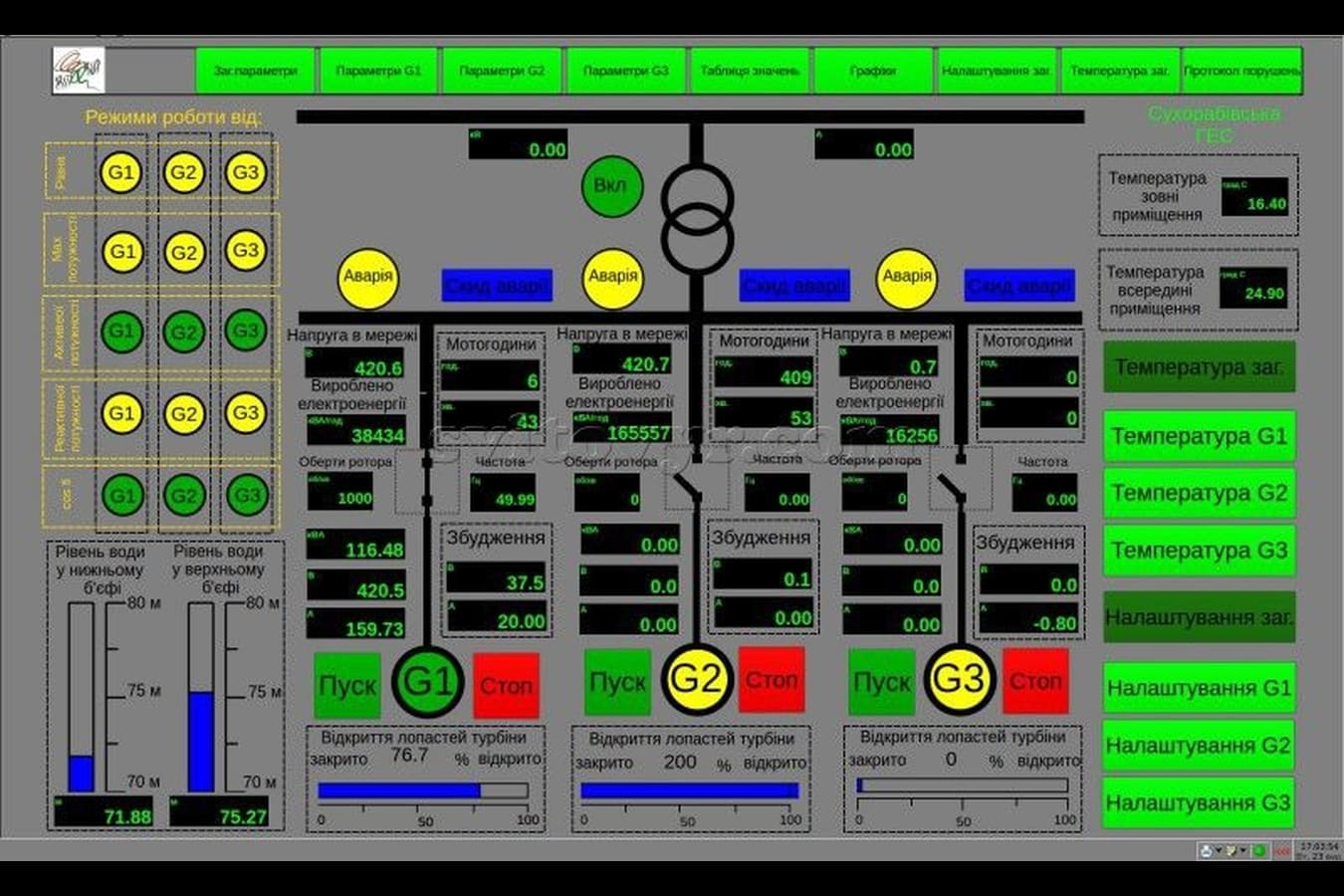

- to its discrete inputs: information from monitor control machines (system start and pause, etc), from additional contacts of commutation devices and from the automatic synchroniser on the possibility of connecting generators to the network and other discrete sensors;

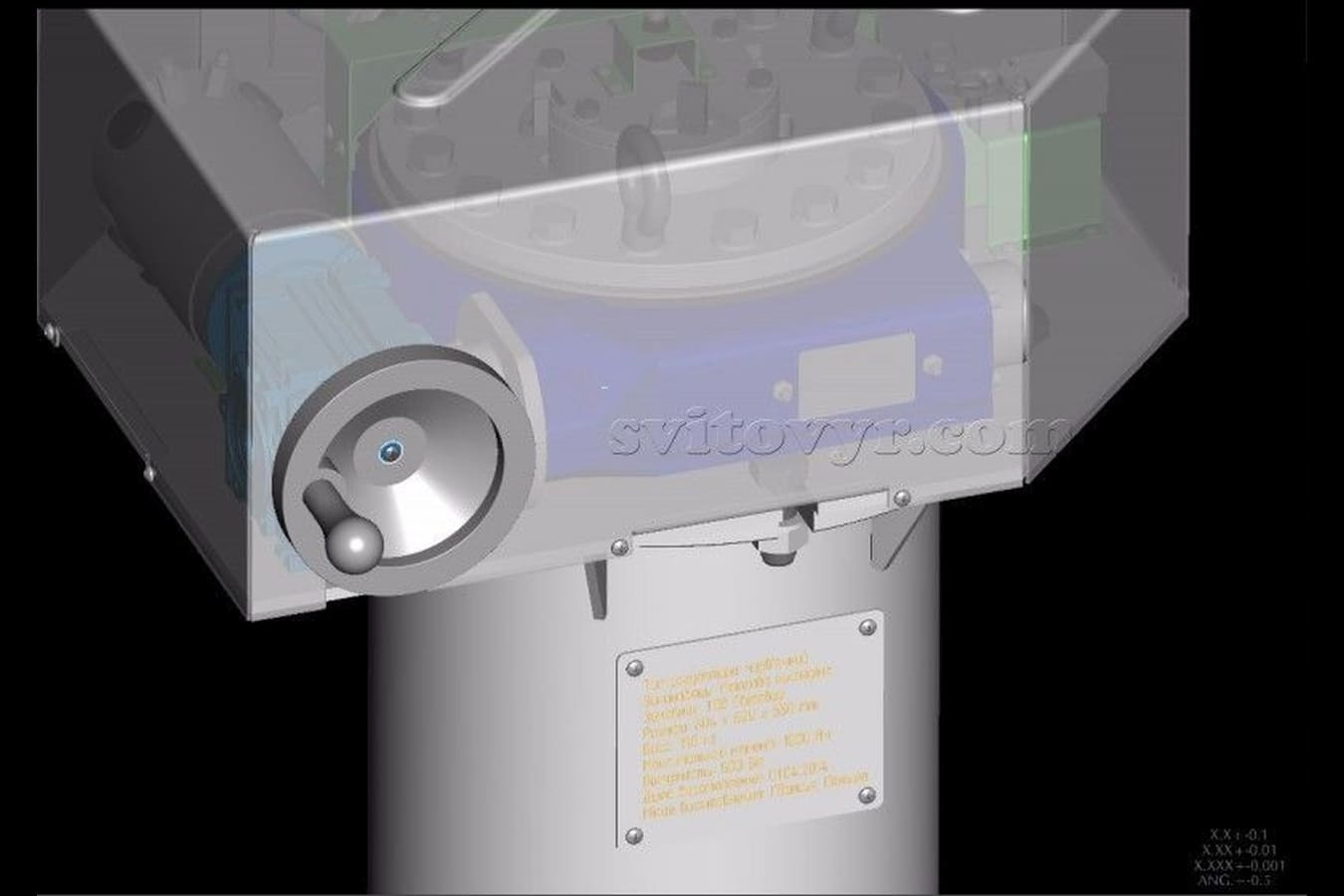

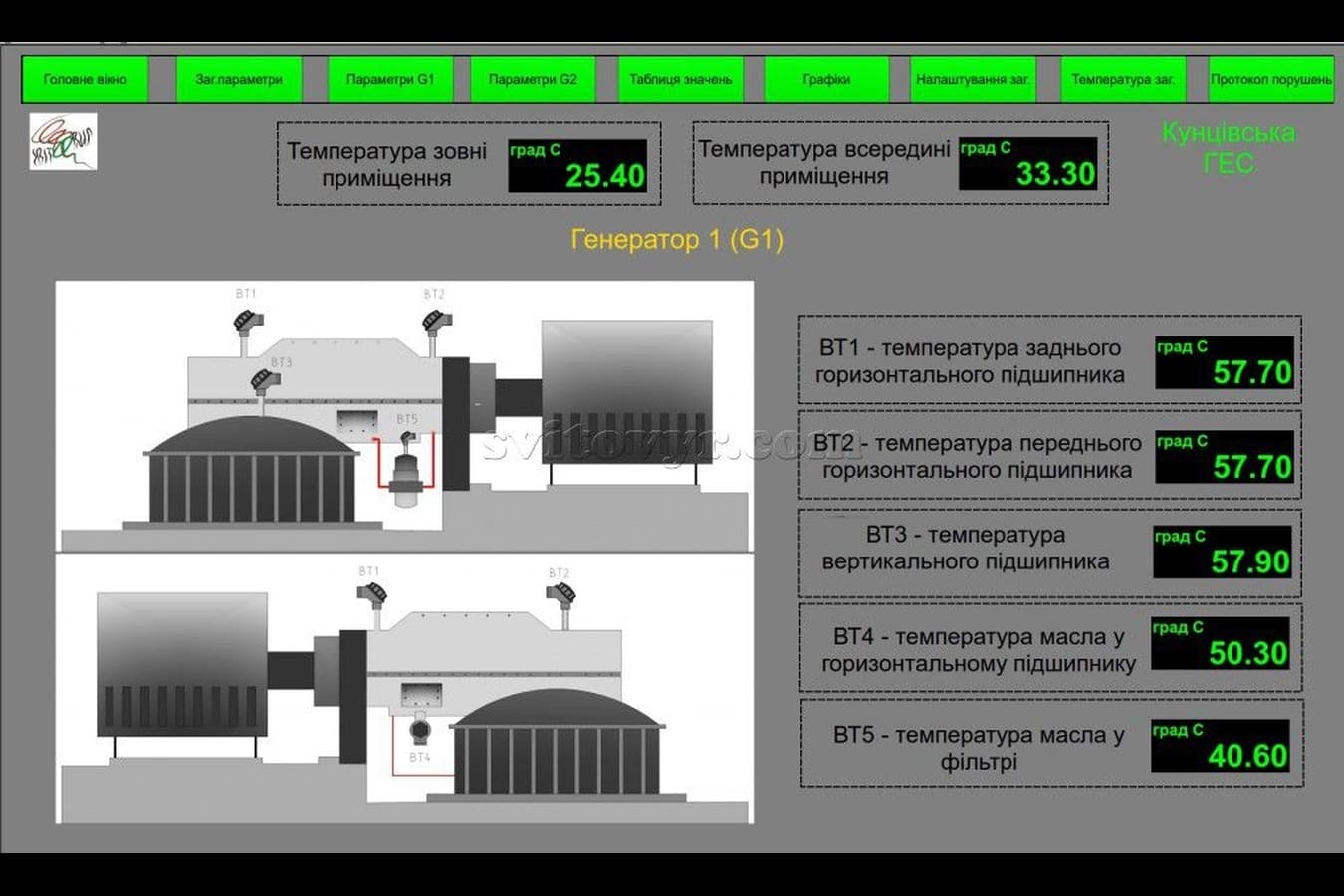

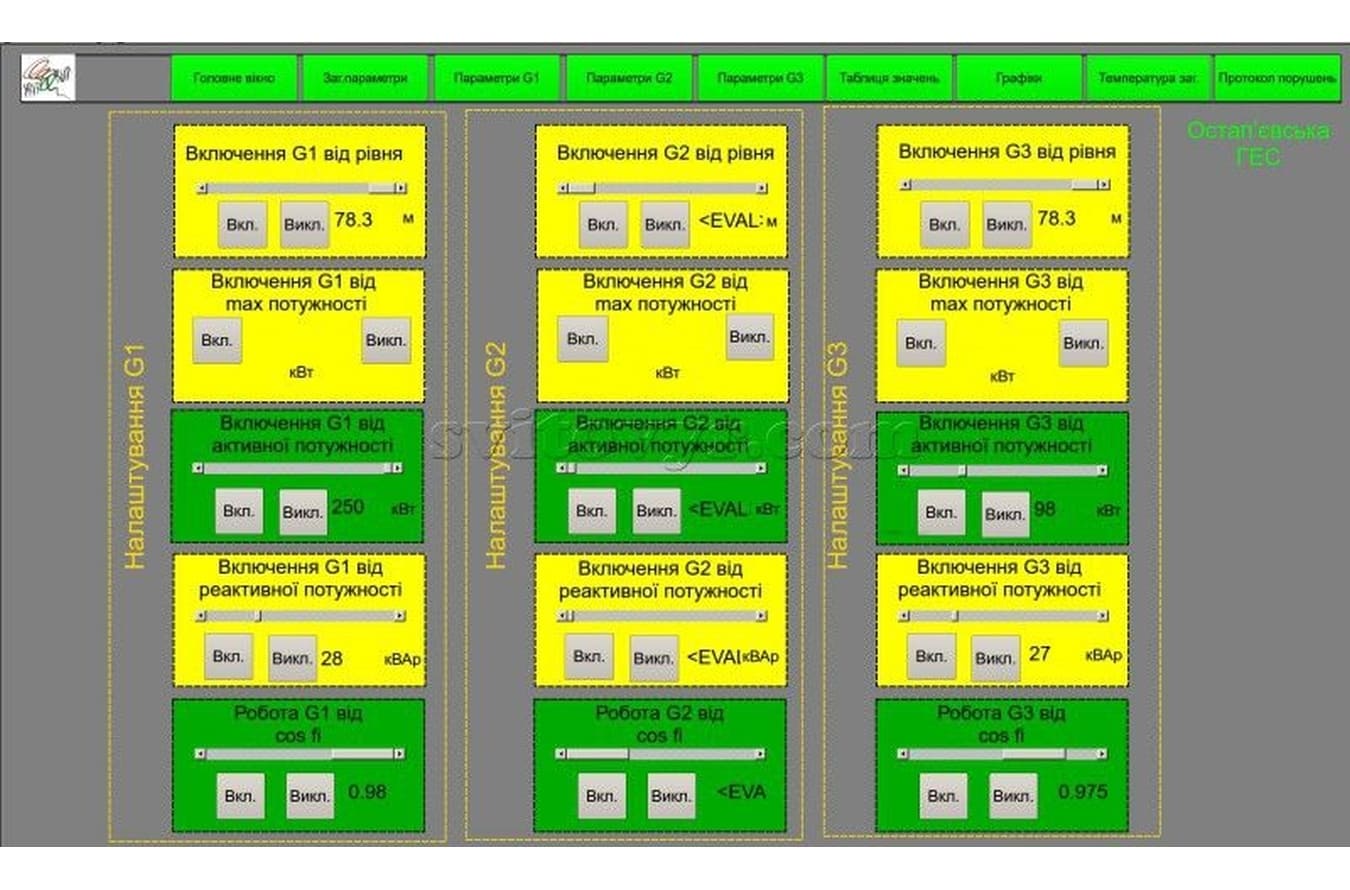

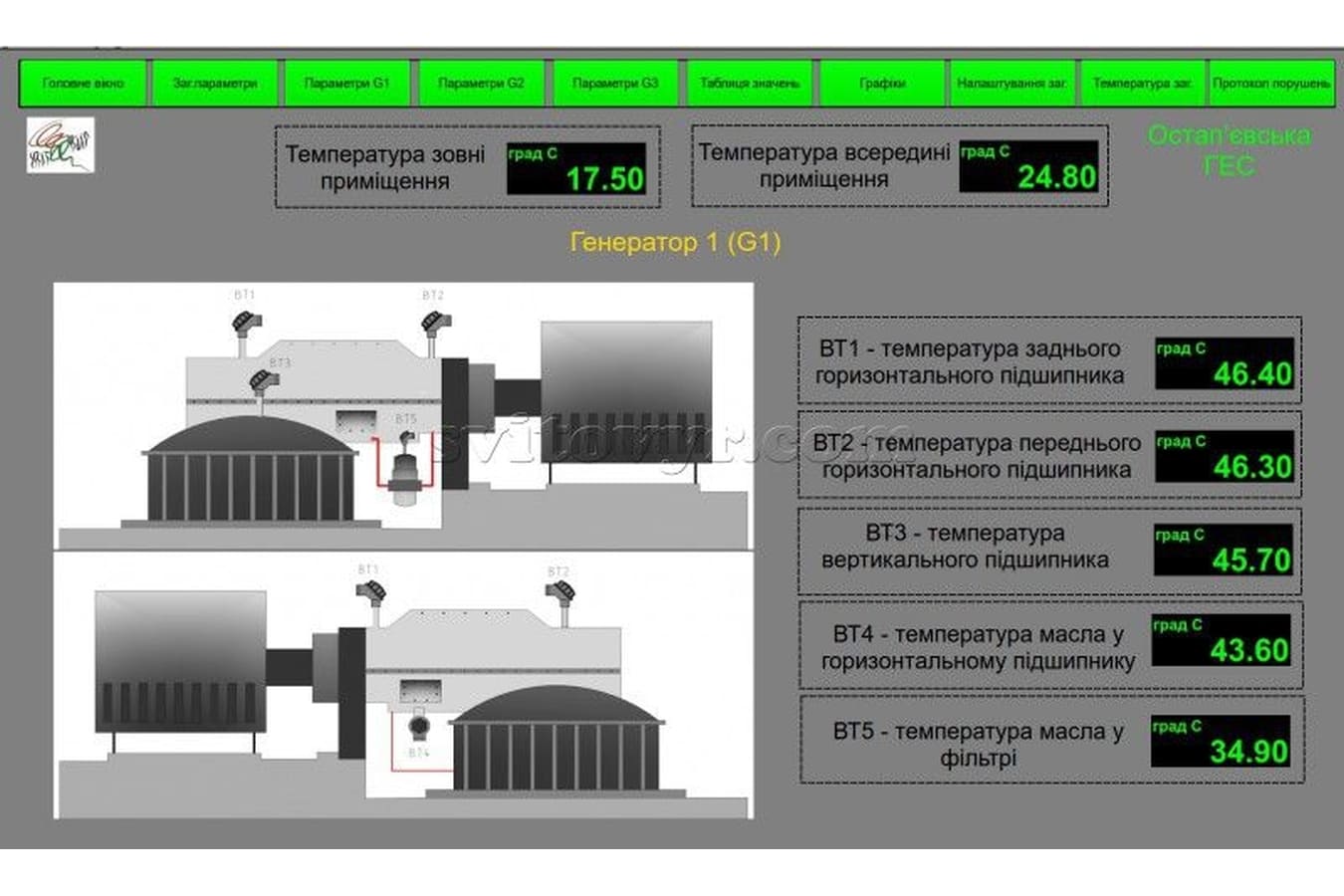

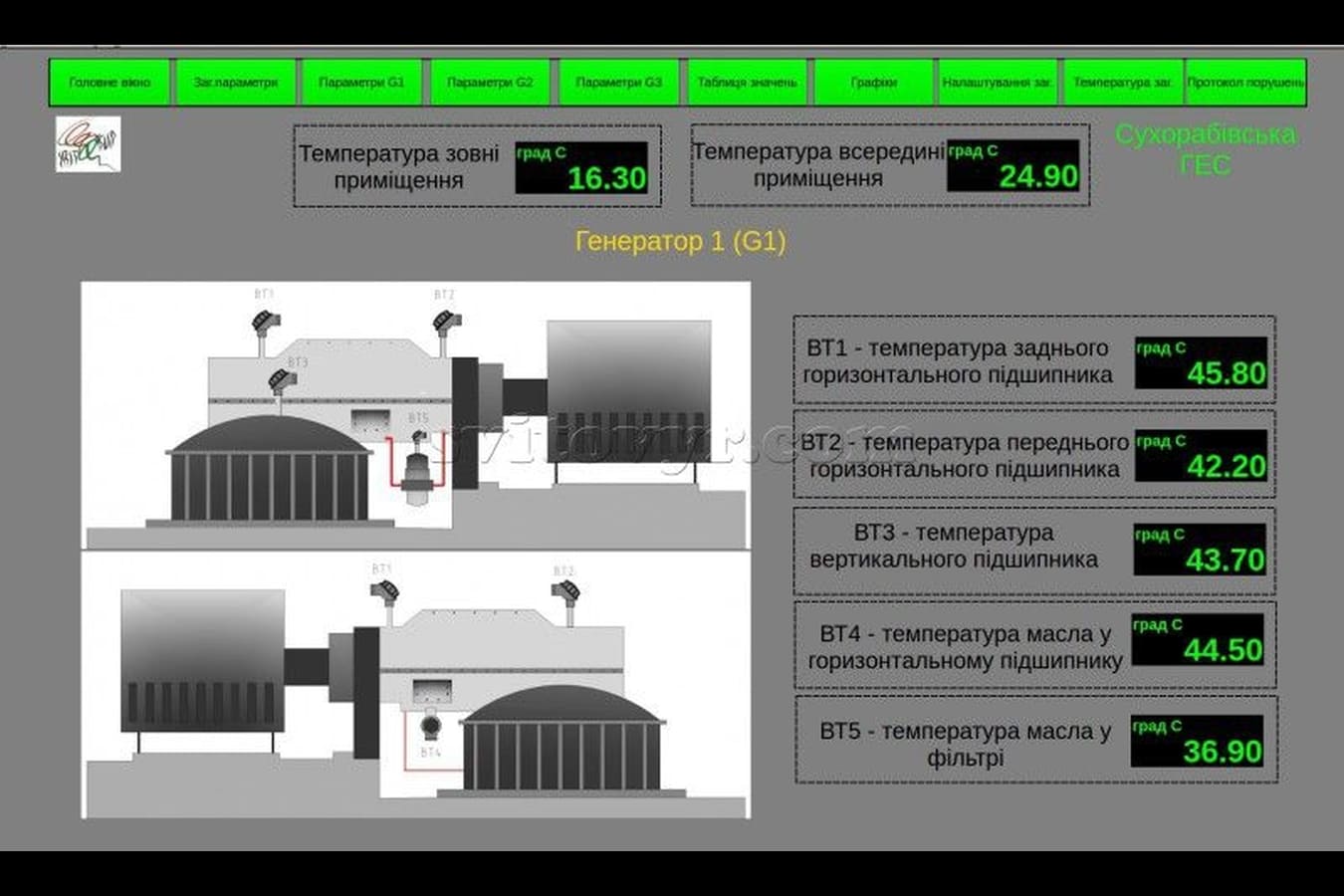

- to its analogue inputs: information on the voltage values and generator excitation currents, temperature of generator stators and water level values;

- to its rapid action discrete inputs: information on the frequency of generator rotor rotation;

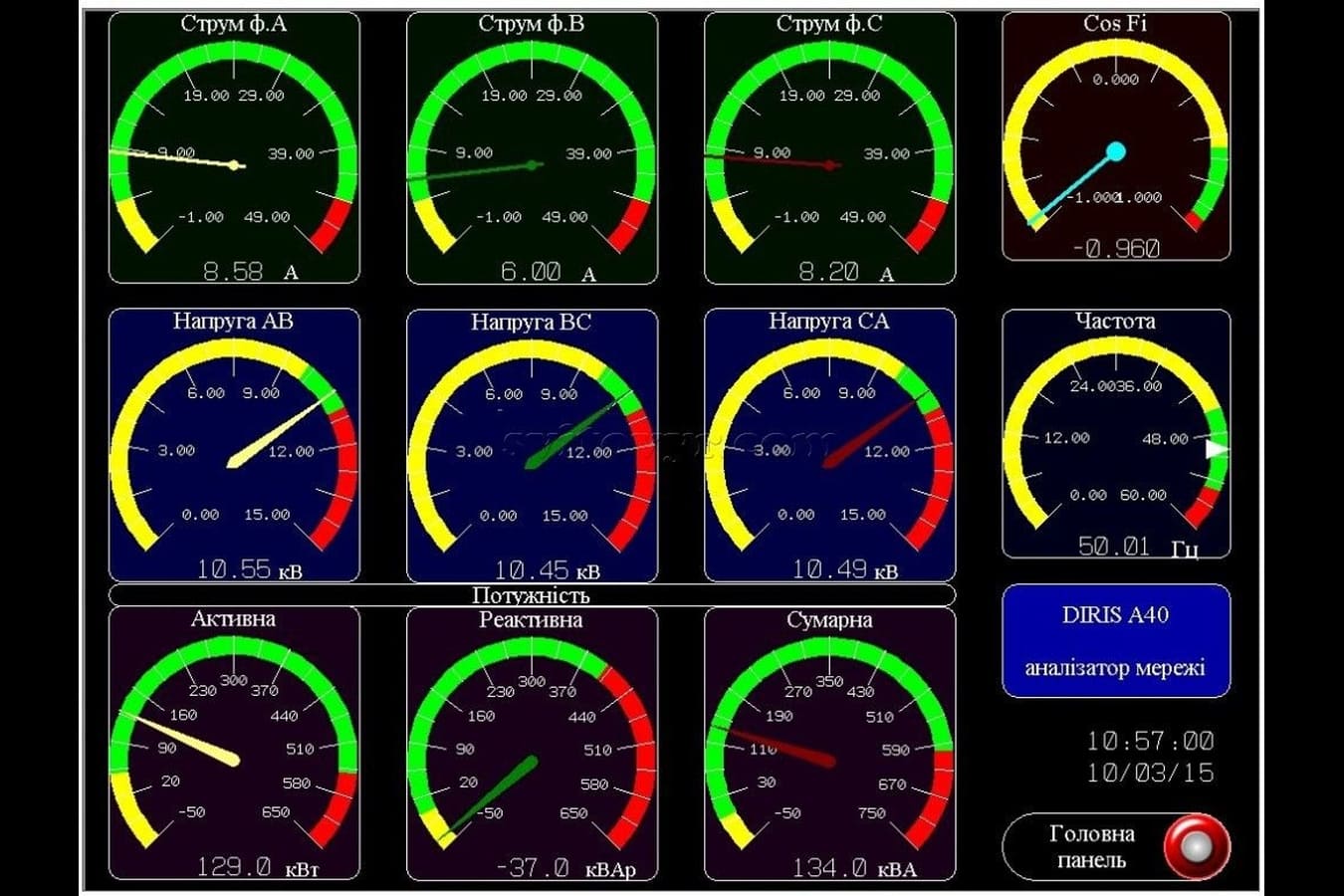

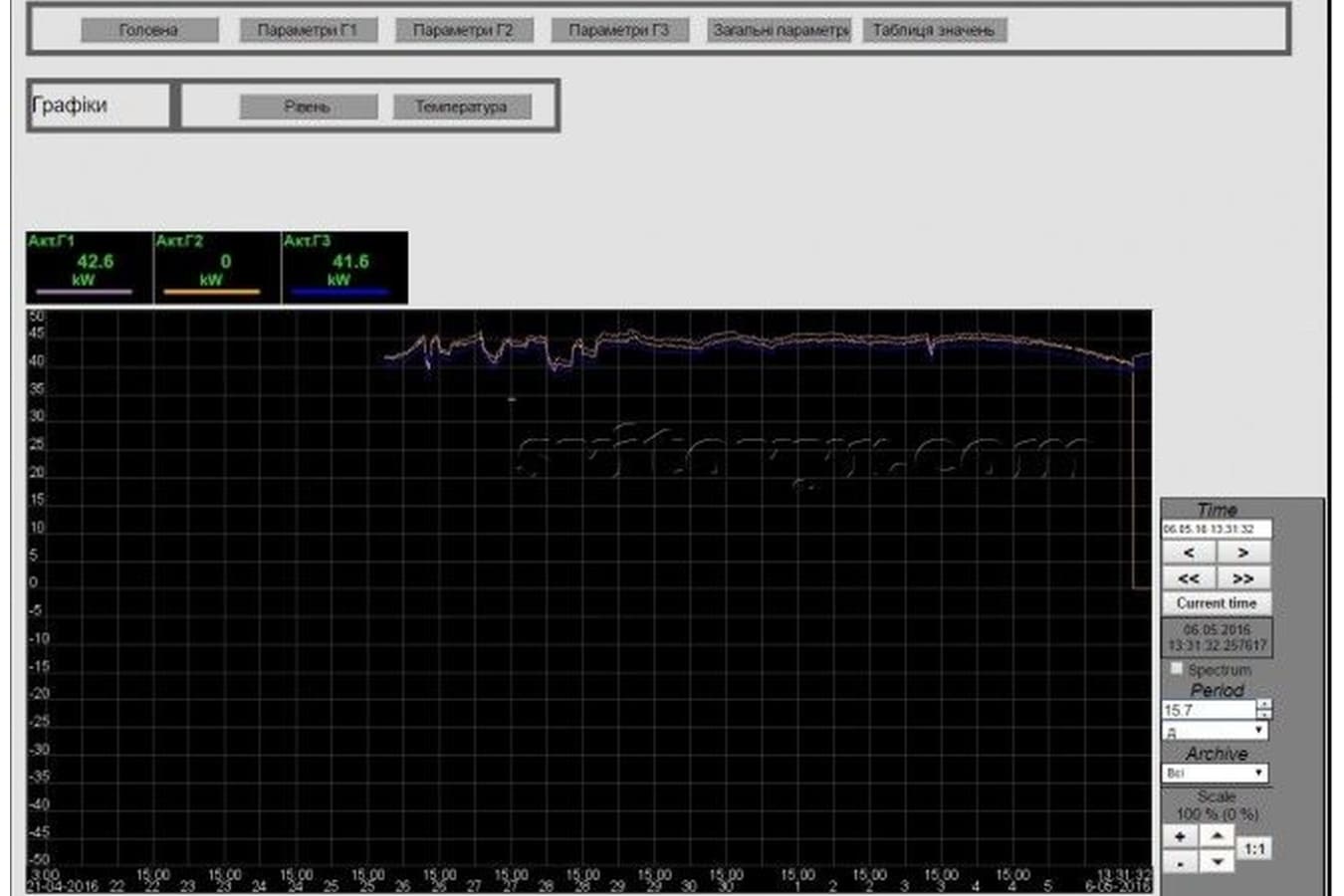

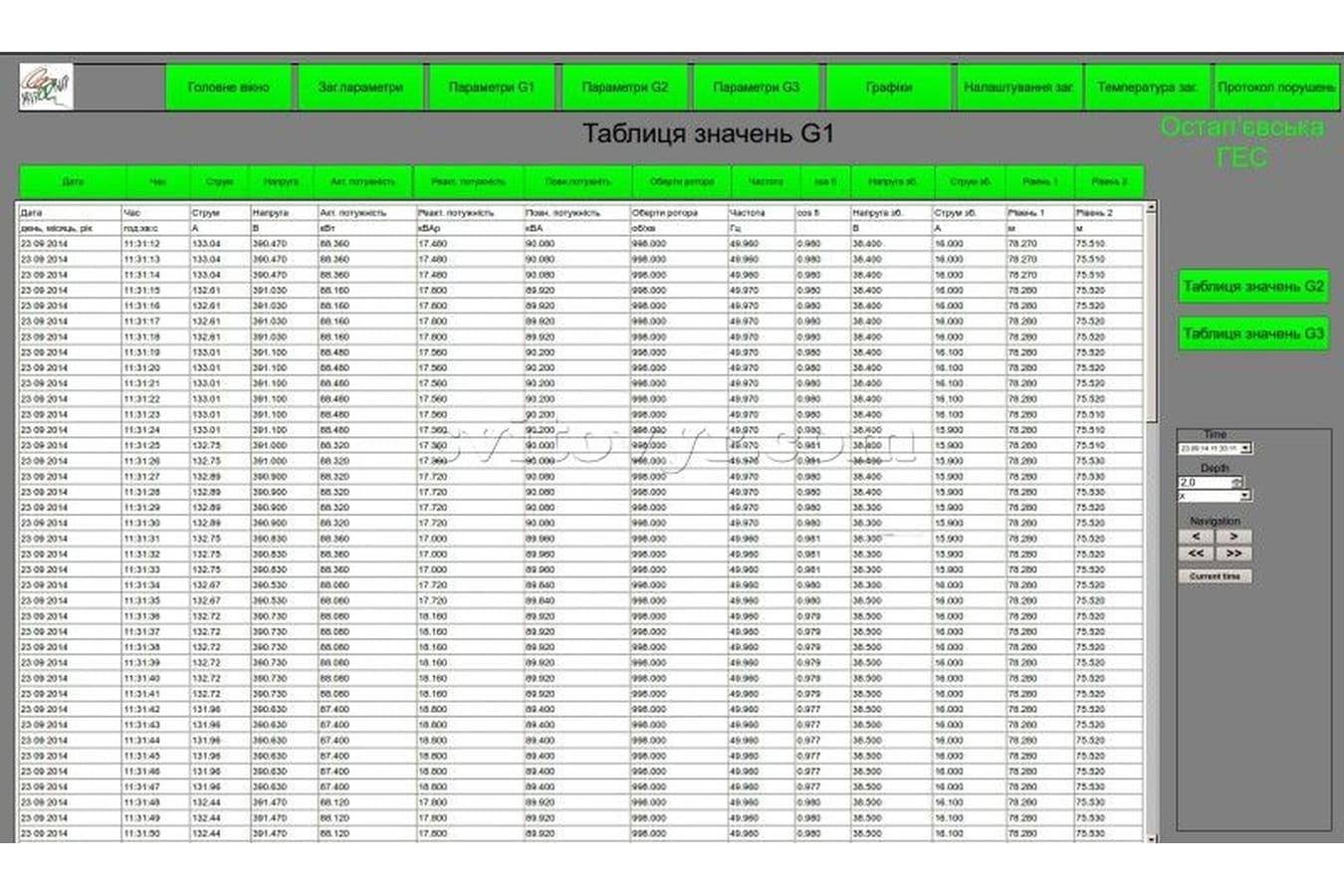

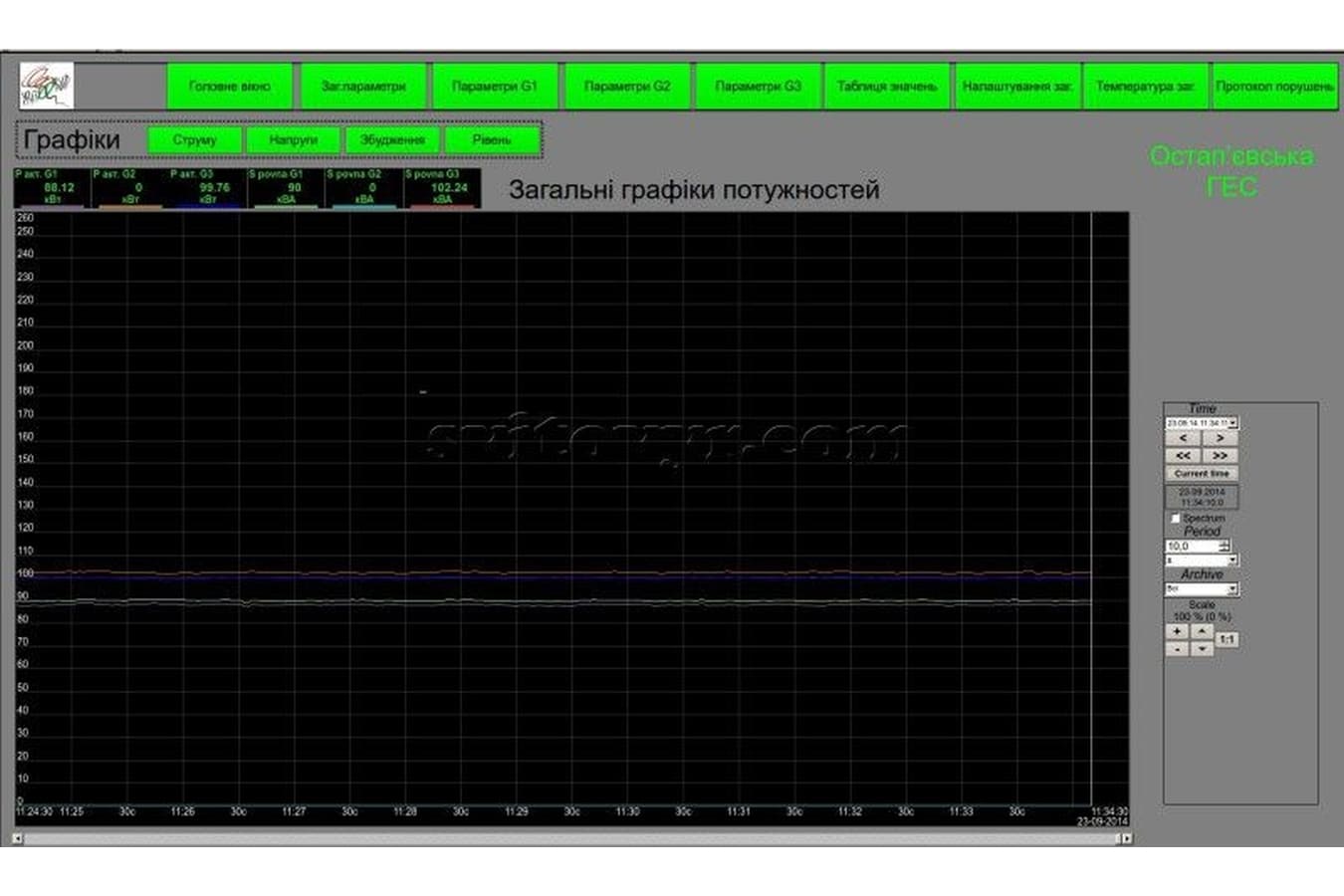

- through the communication channels: information from the digital multimeters (network parameters analyzers) on the values of the electric parameters of the generators.