20 years

The company's activity on the market

2002 - 2022

35

industrial solar and hydroelectric power plants

2016 - 2019

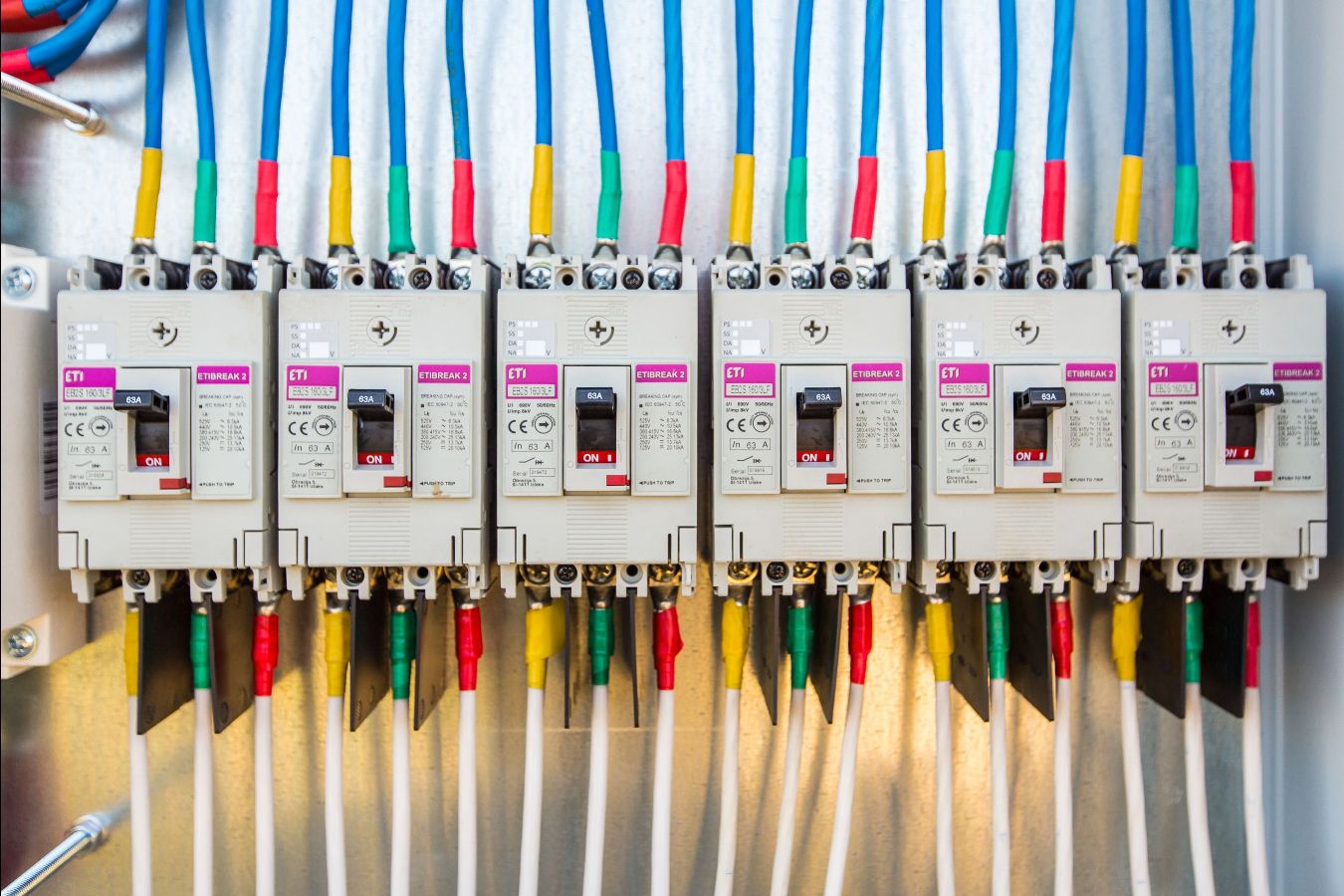

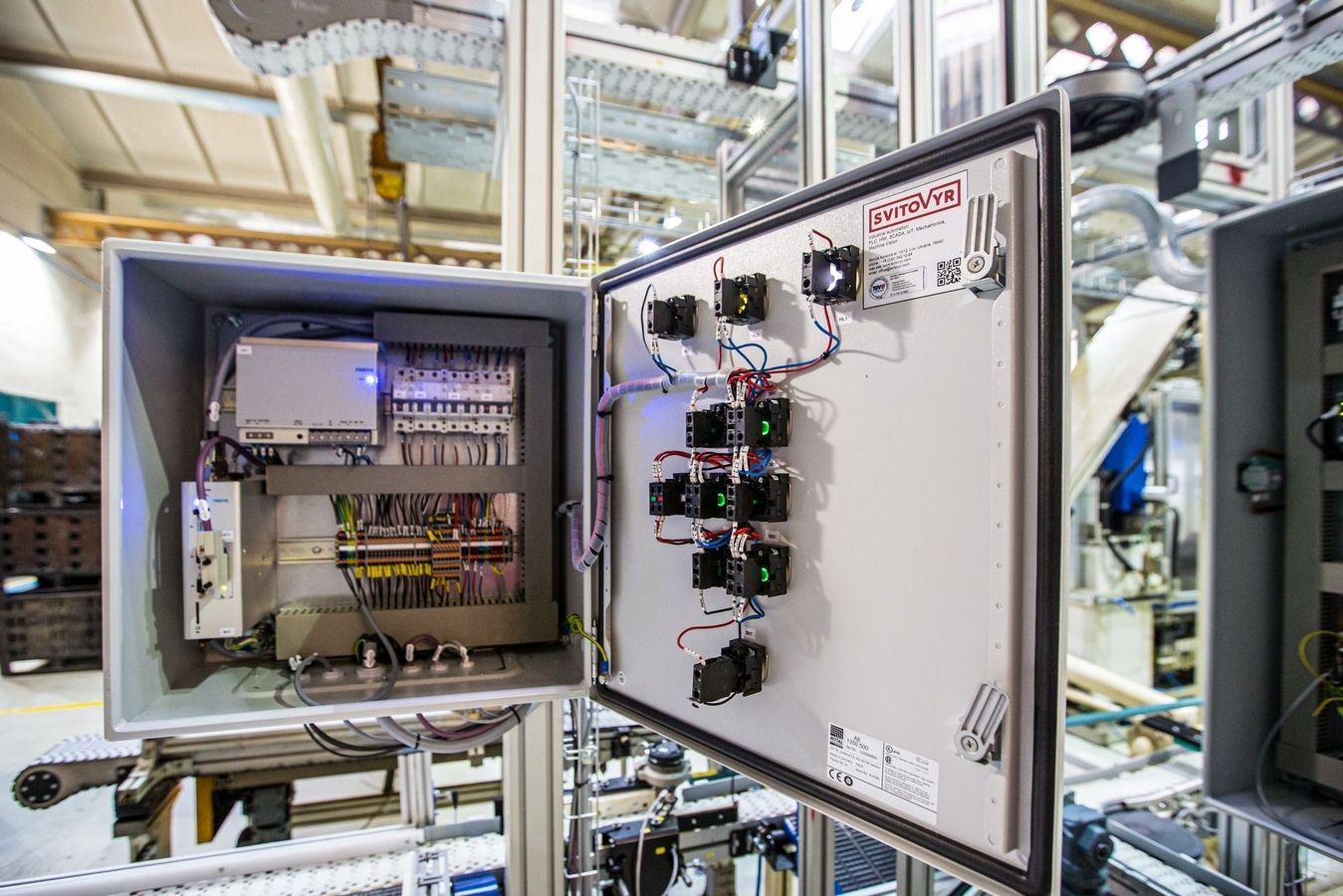

1200

made of electrical cabinets

2014-2019

175 МW

Renewable energy is launched

2008-2019

Services

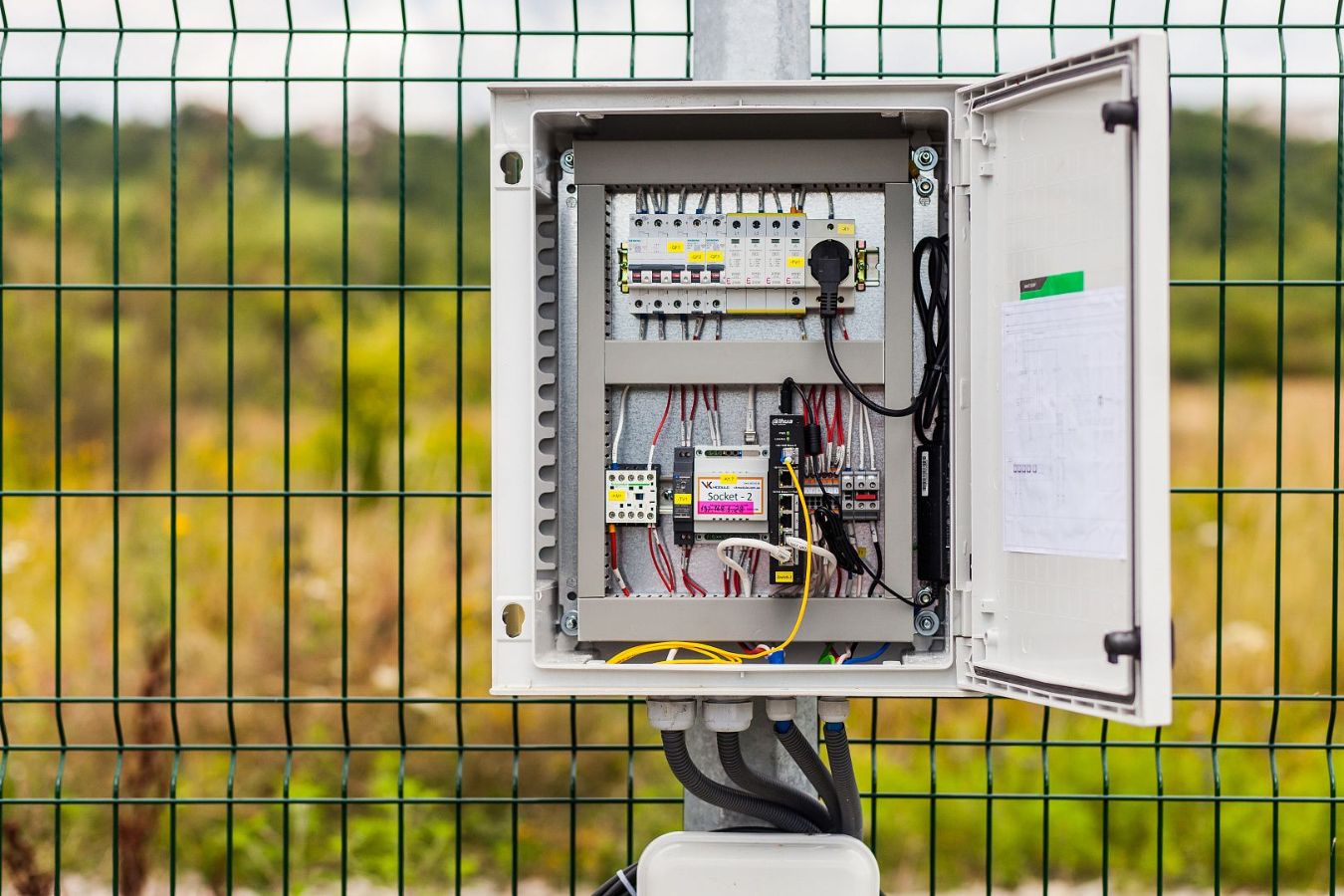

ELECTRICAL INSTALLATION WORKS

- PHOTOVOLTAIC POWER STATIONS

- HYDRO POWER PLANTS

- WIND POWER PLANTS

- THERMAL POWER PLANTS

- Substations

- Underground cable network, overhead lines

- HV cable joints, termination & connectors

- Electric lighting

- Lightning protection

- Earthing

- Prefabricated transformer substation, electrical substation, indoor switchgear, outdoor switchgear

- Service of energy facilities

Areas of activity

reviews

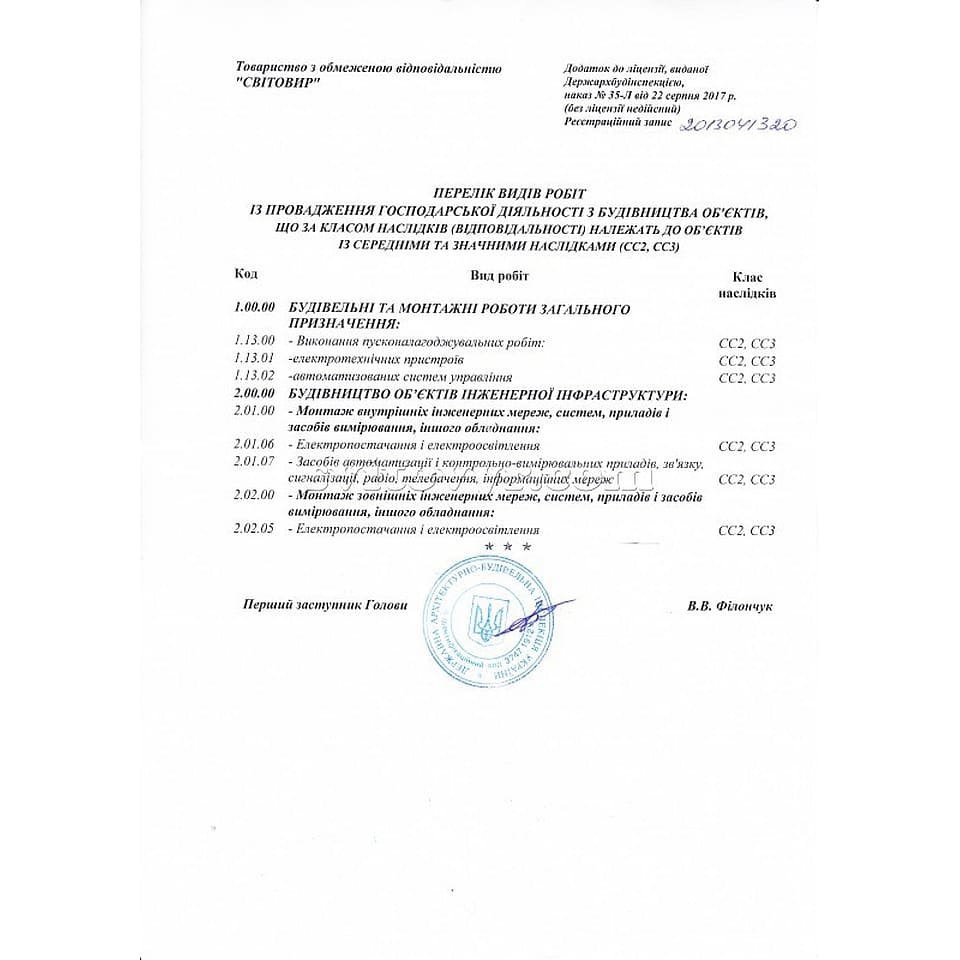

LICENSES

Partners

CRM-форма появится здесь

Feedback

If you are interested in our activities, you want to cooperate, or have specific questions - leave a request by filling out the form in the left column and we will be sure to contact you.

ADDRESS

st. Danyla Apostola, 10/313, Lviv, Ukraine, 79040

MOBILE PHONE

+380673334500

© 2020 All rights reserved.